Training webinar from Hexigon

Sheet metal fabrication involves the design and manufacturing of sheet metal components and assemblies. It is essential for industry verticals including automotive, aerospace, industrial equipment, electronics, medical, oil and gas, and consumer products.

The key challenges faced by the sheet metal industry include:

- Optimising raw material sheet utilisation to save on raw material cost and therefore overall product cost

- Designing sheet metal parts faster, taking into account manufacturing capabilities/constraints

- Optimising the manufacturing cycle time for sheet metal parts

- Ensuring first time right manufacture every time and minimising rejection and rework

- Ensuring smooth execution of manufacturing activities to meet the delivery date to the end customer

- Ensuring the quality of the finished product irrespective of operators’ skill levels

- Optimising the overall product and project cost

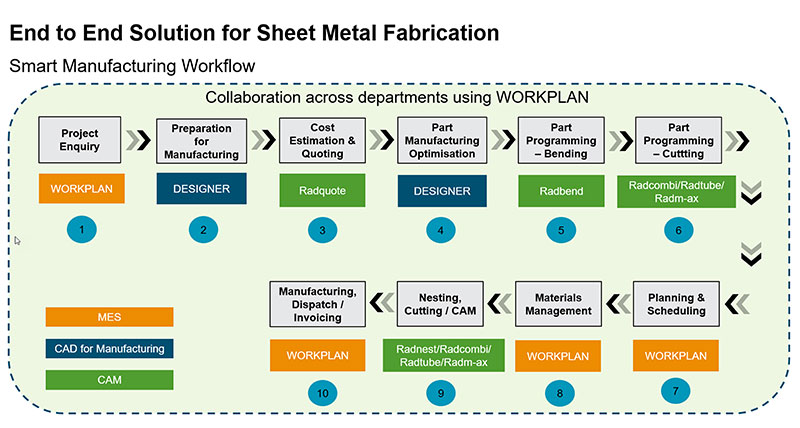

Hexagon’s end-to-end solution for sheet metal fabrication addresses these business challenges at each stage of the workflow from inquiry to dispatch using a smart manufacturing approach based on RADAN, DESIGNER and WORKPLAN.

Key benefits of Hexagon’s end-to-end solution for sheet metal fabrication include:

- Seamless integrated workflow for ease of use and faster training

- Optimisation of raw material sheet utilisation

- Optimisation of manufacturing cycle times Better resource utilisation for equipment and operators

- Optimisation of overall product and project cost

- Better control over the quality of the product

- Faster time to market, ensuring on-time deliveries to the end customer