WORKPLAN

WORKPLAN Quality

The WORKPLAN Quality module allows you to track separately time and costs associated with quality issues. This module is not only a great help to get the ISO certifications and meet ISO requirements imposed by your Quality Management System (QMS), but it will manage suppliers’ evaluation and gives access to cross-functional features to improve your Quality and meet your company’s policy and involvement towards your customers. Additionally, the maintenance of measuring devices used in quality assurance, quality indicators and KPI analysis are a key to succeed in getting your ISO Certificates.

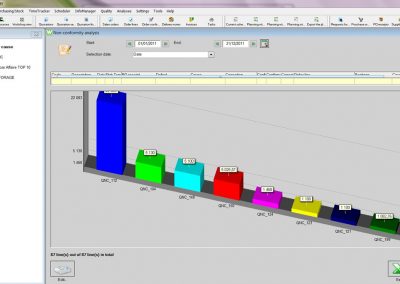

- Quality cost calculation and analysis

- Supplier’s evaluation and rating

- Continuous improvement

- Quality certification support tools

WORKPLAN’s Quality module allows you to track costs associated with quality assurance at your facility. Costs of downtime or other items that affect profits, yet are not part of the regular manufacturing process are tabulated and available.

Use the quality module to manage and schedule regular maintenance on items used in measurement of quality assurance. Distribute quality standards and all related documents to all relevant employees.

Assign non-conformities reported to either a customer, supplier or to an internal task or production operation. Easily create non-conformity sheets by dragging and dropping, entering the defect, cause and corrective action taken for future reference.

Enter the criterias to evaluate your suppliers. Create reports that can be used in future decision making regarding particular suppliers not meeting deadline, quality requirements, or costs agreement.

Contact

Current customers

Sales

inquiries

If you are interested in any of our servies and software please contact us via our Sales contact page