WORKPLAN is a project management and production software designed to automate business processes and support administration for the mould and die, sheet metal, machining and prototyping, and woodworking industries.

Our software continuously manages your business, from quotation creation to raising the final customer invoice, and all steps in-between.

Customer-specific or project-related companies often find it difficult to find a Production Management System that adapts to their individual needs and focuses on the job or project. The flexibility and adaptability of WORKPLAN is its strength.

The user interface can be individually adapted to your needs and can therefore be used intuitively.

There’s no production downtime caused by cutting tools not being available, which is due to be the management module and real-time data capture.”

Daniel Lelaure,

Technical Director Metra

WORKPLAN provides the tools that put you in control

CRM

- Manage activity of sales team

- Manage, track and follow up on sales opportunities

- Synchronise activities with Outlook

- Accurately forecast sales:

- Timeline: activity summary

- Control actions over time

- Screens, alarms and notes customised per user

Quotations

- Quickly prepare your technical quotes (production tasks & materials)

- Excel Interface and WORXPLORE 3D view manage quotation versions

- Capitalise on existing data thanks to technical criteria

- Send quotations directly from WORKPLAN via e-mail

- Automatically convert quotes into sales orders:

- Rapid, reliable and precise quotations

- Automation and centralisation of technical data

- Optimise profit margins

Manage sales team activity

- Progress from the sales order through to the customer Invoice in just a few mouse clicks

- Easily store and recover all project associated documents

- Increase profitability on jobs

- Utilise built-in tools to aid decision making:

- Sales administration

- Real time project summary

- Easy access to documents

Purchasing – Stocks

- Automate and import bills of materials (native Hexagon product interface and other CAD systems)

- Management of purchasing and sub-contracting processes

- Real-time stock reporting

- Multi-location stock management and inventory control:

- Simplified purchasing procedures

- Production cost control

- Stock optimisation

- Calculation of material requirements

Production Management

- Employee management: skills, time and attendance (clock-in & clock-out) and payroll interface, work schedules and leave requests

- Machine resource management: grouping of services and capacity

- Parts quantity management, job time tracking by manual data input using a bar code reader or touch screen

- Manage machine and equipment maintenance, schedule maintenance operations and measuring equipment calibration programs

- Obtain up-to-the-minute information about absences, machine capacities, sub- contracted component statuses and WIP:

- Workshop operation times

- Supervision of production process

- Factory view with real-time snapshot of your workshop

- Tools to share information: instructions, documents and comments

- Check material availability

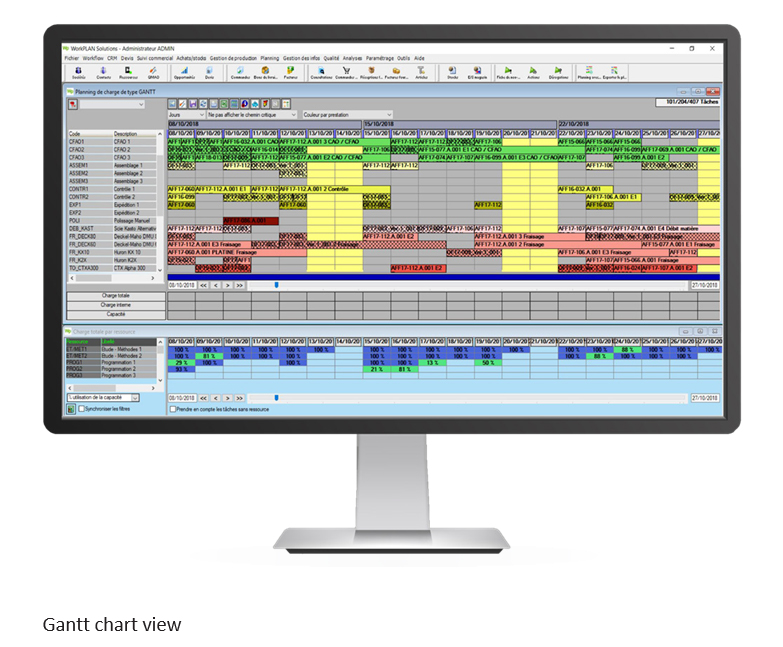

Planning

- Simulate completion deadlines according to workload

- Gantt Chart and Pert Diagram

- Prioritise projects according to constraints and milestones

- View by projects or by resources

- Validate customer delivery deadlines with overlaps

- Standardise printing for workshop schedule:

- Rapid workload analysis and visualisation

- Optimise your resources

- Export to Excel

- Planning view for workshop

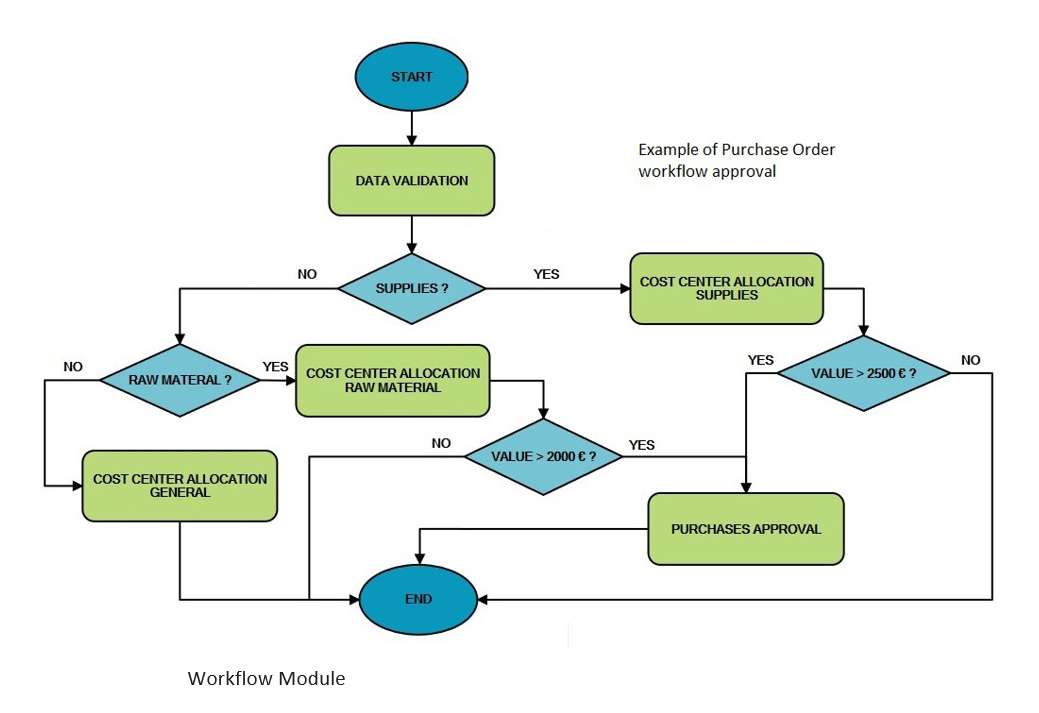

Workflow

- Controlling document creation and validation by defining several steps

- Pre-defined workflow or free workflow –

- Personal Inbox information to follow steps based on functional organisation chart

Quality drives profitability

The essential tools needed to drive your business and optimise your productivity:

- Job line report

- Non-conformity management

- Supplier evaluation

- Measuring equipment calibration programs

- KPI and quality indicator

- HomePage

WORKPLAN MES, the key to your success

WORKPLAN No 1 solution for mould & die

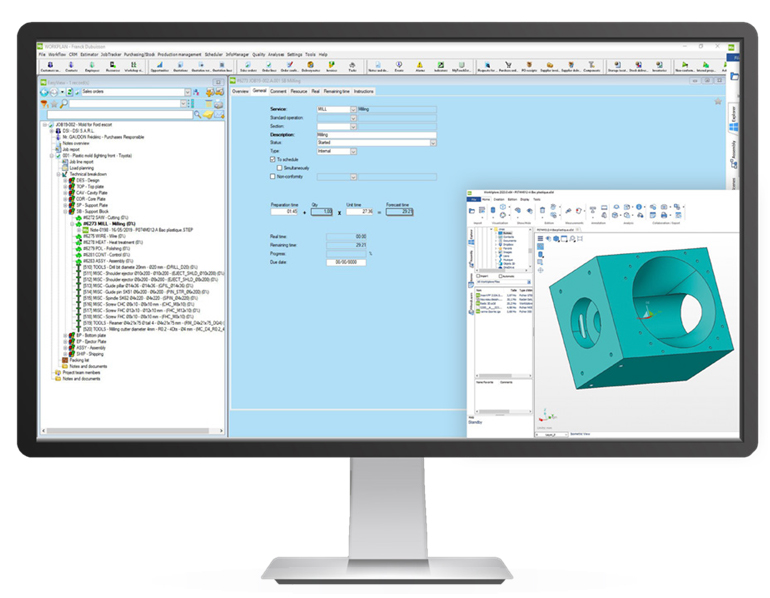

Import bill of materials (BOM): assemblies, components, materials, dimensions, comments and 3D view with the ability to automate the creation of technical breakdowns with standard manufacturing processes.

CAM interface with WORKNC and EDGECAM

Synchronisation with CAM program to download forecasted time and update production processes. Direct link for tools used and project technical documentation with full traceability.

MES additional functionality

- CMMS

- Part traceability

- Part location on work-shop

- Packaging management

- Live machine monitoring links

- Process documentation

- EDI / API

- OEE (Overall Equipment Effectiveness) calculations

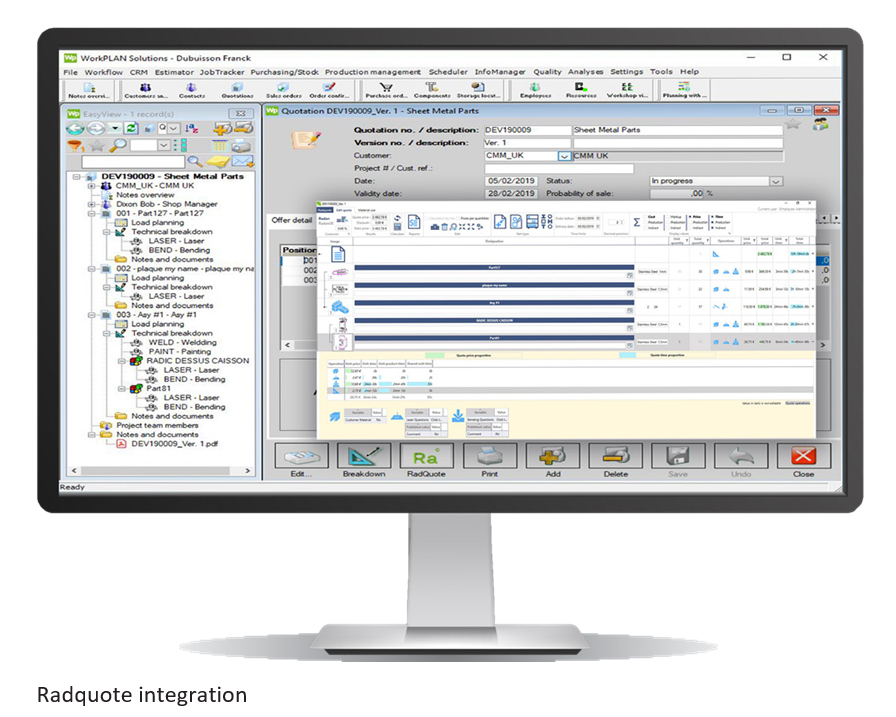

WORKPLAN FOR THE Sheet metal sector

WORKPLAN utilises a powerful dedicated Sheetmetal pricing tool which includes material costs and forecasted production times:

- Sync part files to illustrate all documents of production with image

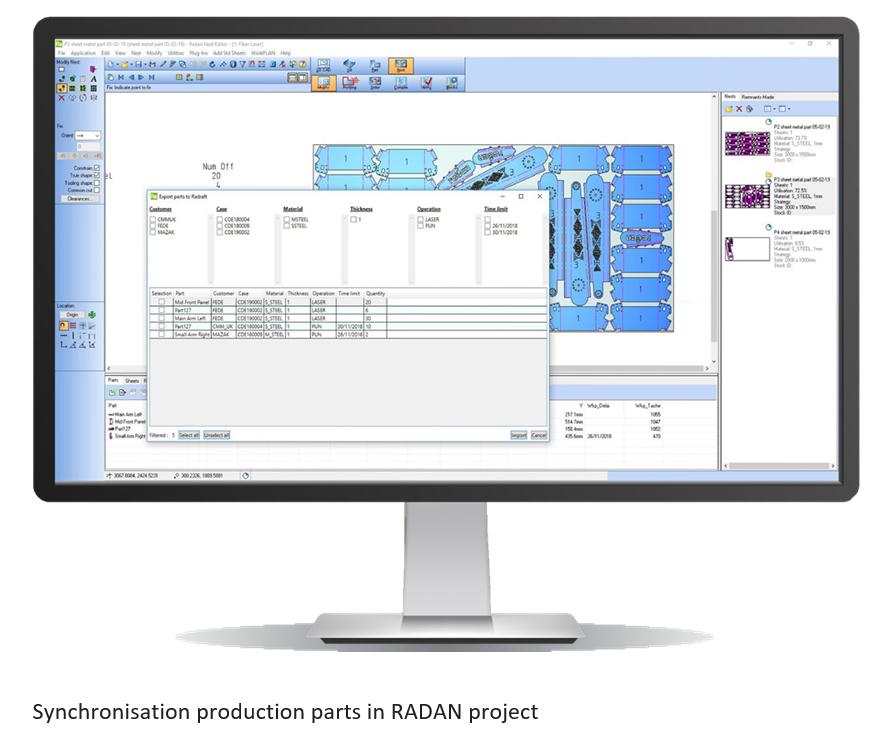

RADAN integration

Directly link between RADAN and WORKPLAN providing fluid data exchange for improved productivity:

- Sheet metal requirement estimation

- Import parts to be produced in RADAN

- Stock Inventory import by material type, format and thickness

- Sync program directly in WORKPLAN to manage the production

Shop interface

- Production management, productive and unproductive tasks

- Real-time allocation on jobs and parts quantities

- Program validation to dispatch time and material on projects