RADAN CAD/CAM 2023.1

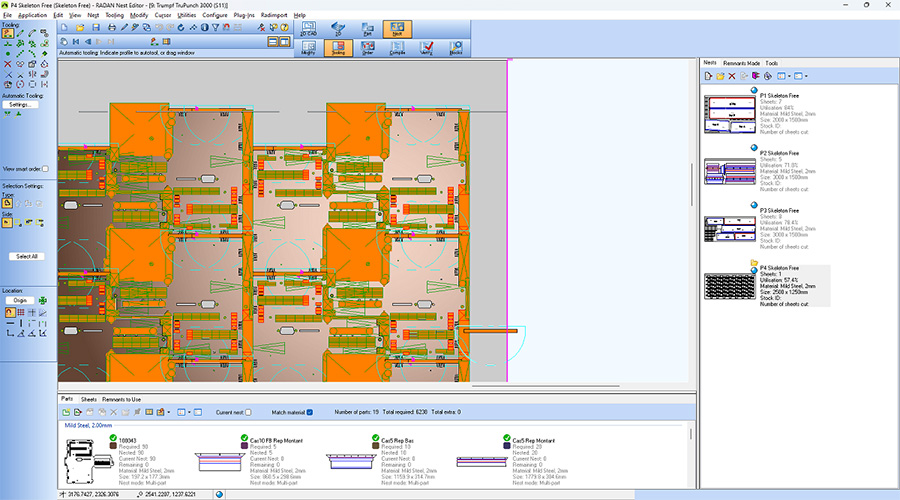

Nest Projects changes

With complex nest projects, it can be time-consuming to complete all work on the nests.

In RADAN 2023.1, the user can use Finish Nest Projects to finalize all nests in a project automatically.

Less time is spent entering data and avoiding costly and time-consuming errors. It allows easy preparation of nests for multiple machine tools.

Floating Scrap

With complex programs, it can be difficult and time-consuming to check the program for errors. RADAN offers a function to check for floating scrap specifically, but it has to be run manually. Floating scrap detection can be included in the automation options and can be made mandatory to create NC programs.

Less time is spent manually checking programs.

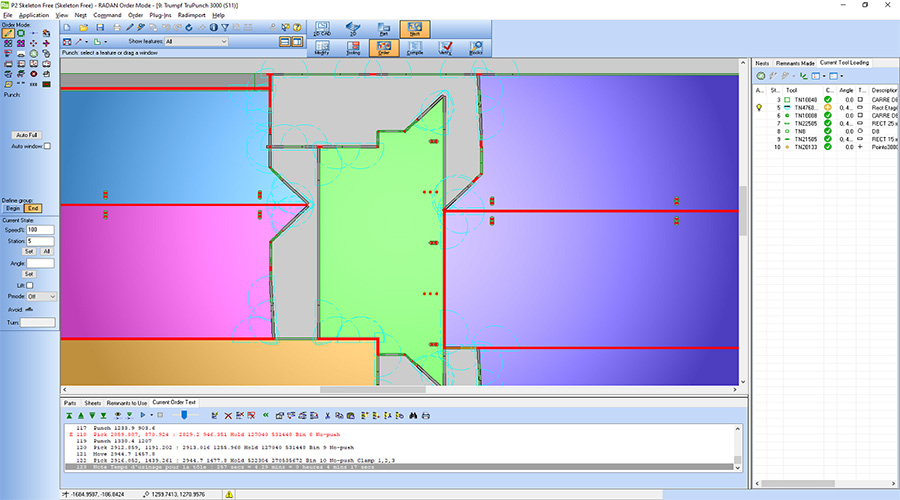

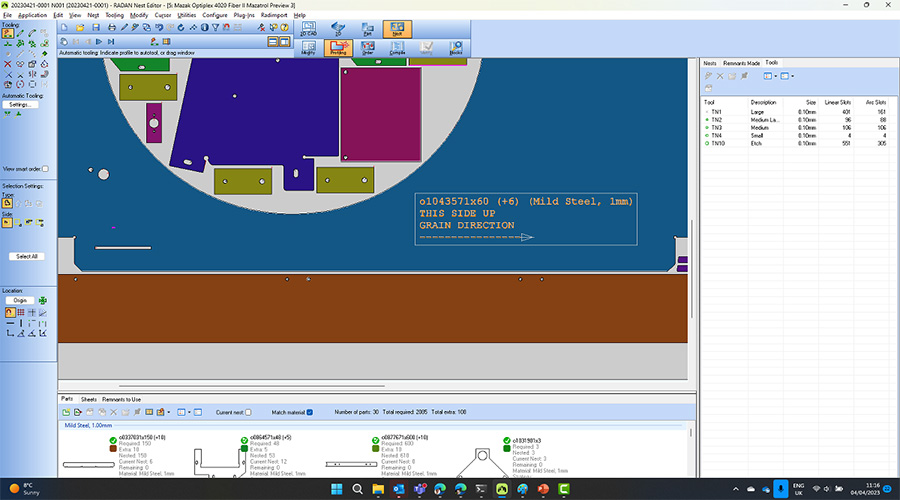

Part Marking

Part marking can contain any combination of information about a part (or a nest), and manually setting the contents of a part mark is time-consuming and error-prone.

Part marking contents can be set in the machine configuration editor and is specific to the machine. It allows the characteristics of the mark to be controlled and allows a template to be used for the contents. This means that the pmdatum itself can be left empty. Part attributes as well as nest attributes can be used. QR codes and DataMatrix codes can now also be configured to be very small.

The part mark can be left empty and configured in a general manner, saving the user time and preventing errors. The time on the machine can be reduced to around 4.5 seconds to mark a part name using QR codes.

Text Marking

To etch text on a profiling machine, the text needs to be in the correct colour and be ‘realized’ (exploded). This means that the text can not be dynamic and is cumbersome to add. Also, text features can only contain drawing attributes and not symbol attributes.

Text can now be etched without exploding it, provided it is placed in the correct etching colour. Text features can now also refer to symbol attributes. This makes it easy to add dynamic text. All text properties are supported, including multi-line, True Type fonts, balloons and special characters. Part marking can be output as readable text.

Dynamic text can be placed on a part or a nest and will be etched without further user interaction, saving time and errors. Human-readable text can be used to avoid the need for scanners.

Common Cutting

Fiber laser machines use very high gas pressures which can cause scrap to come loose and cause a hazard. Currently, when using common cutting, it is difficult to automatically tag potentially hazardous pieces of scrap. Also, nesting when using common cutting is not always producing an optimal result.

Small pieces of scrap are now automatically tagged. Also, Radnest Ultimate is now used to create nests with ‘true’ unrestricted common cutting.

Without additional work by the user, common cutting is now safer than previously, and the nester provides improved material usage when using unrestricted common cutting.

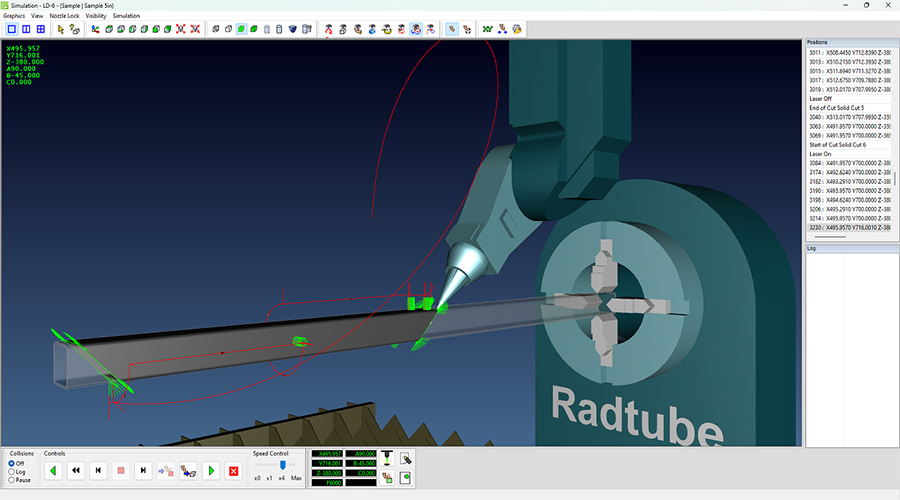

Radm-ax / Radtube

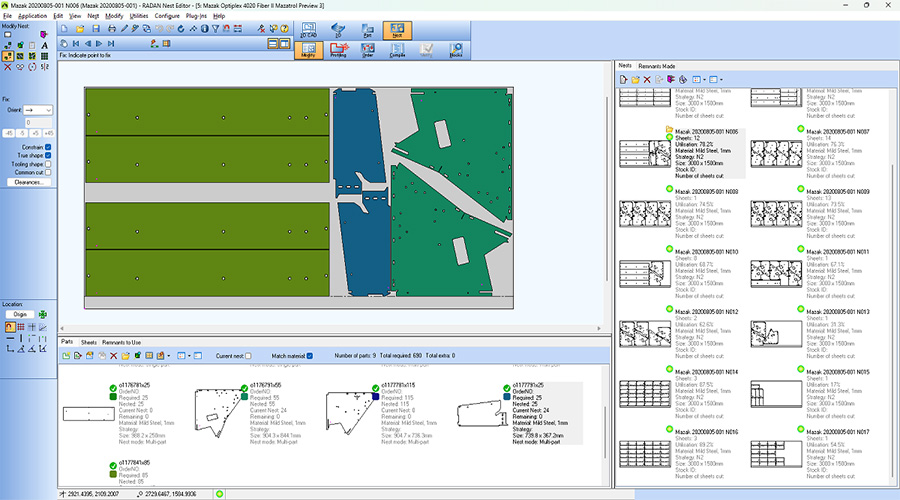

Multiple Stocks

Tube stock can be purchased in different lengths, and it can be difficult to keep stock levels. Additionally, tube stock can be uniquely identified in a stock management system, and it needs to be tracked.

Radtube can now manage various stock lengths when nesting and tracking stock identifiers. The information can be entered manually or imported through CSV files and is tracked all the way to reports and – for some machines – the NC code.

Stock IDs and quantities are now properly tracked, and the nester will take current stock levels into account without user interaction. The correct information is passed to the operator so fewer mistakes are made. Mazak machines allow the stock ID to be sent back to the planning system through the NC code.

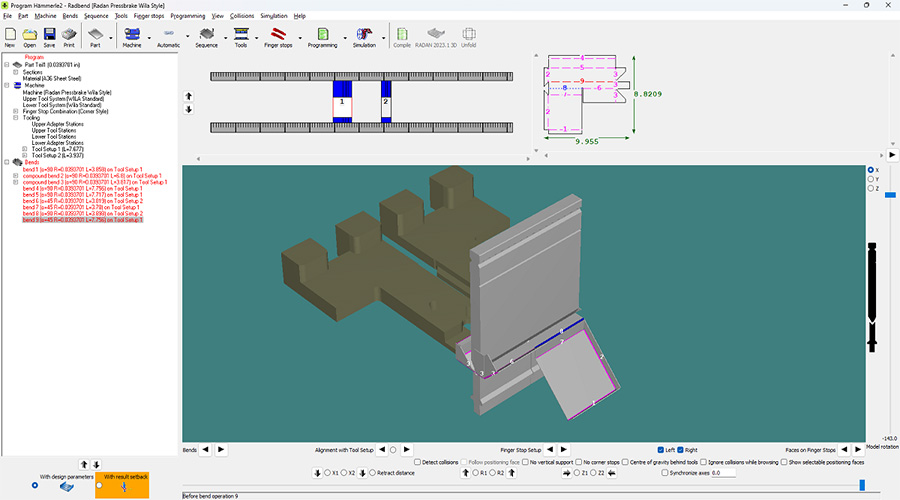

Radbend

Small tools have less scope for clamping and may be unstable. Using these small tools on the outside of a tool setup is not desired.

Smaller tool segments can now automatically be placed away from the outside of a tool setup. In addition, any tool segment can be marked so that it is never placed at the extremes of a tool setup.

Improved tool stability without additional work for the programmer when preparing the programs.

Radquote

Preparing a quote for a large number of parts can be laborious and error-prone. Radquote now allows you to import a list of parts using a CSV file. Less time spent manually entering part details and less scope for errors.

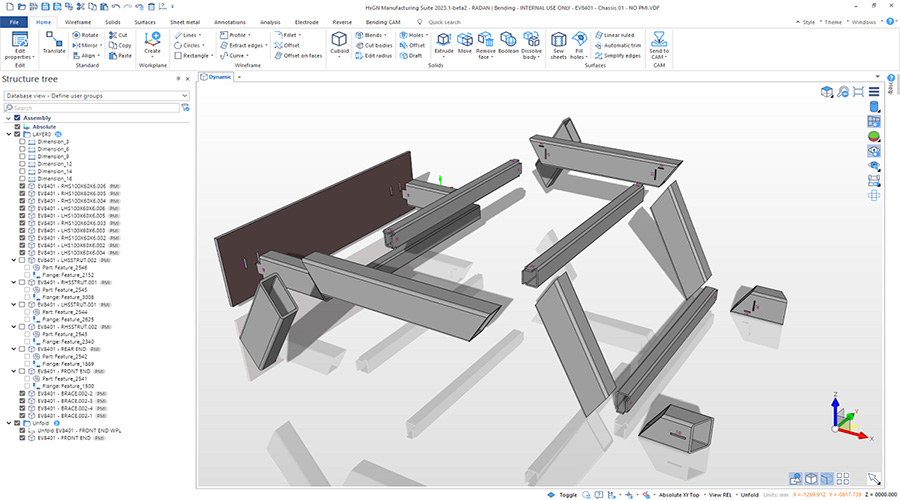

DESIGNER

Assemblies

With complex assemblies, it can be time-consuming and error-prone to create a Bill of Materials containing purchased parts and manufactured parts. In addition, more detail is required in the Bill of Materials to support the purchase or manufacture of the parts.

In DESIGNER 2023.1, the user can ask the system to automatically set the 1D shape specification on recognized sections and can manually set the shape specification on other sections. The Manufacturing Pack now contains dimensional information of manufactured parts.

Less time spent entering data and avoiding costly and time-consuming errors. DESIGNER can now create a simple cut list of certain part shapes.

Sheet Metal Features

DESIGNER is a good tool to create 2D drawings, but it didn’t support sheet metal-specific information very well.

It is now possible to add key information such as manufacturing material to a 2D drawing, including bend details. A new option allows the bend zones to be hidden.

More information that can be passed to, for example, a machine operator.